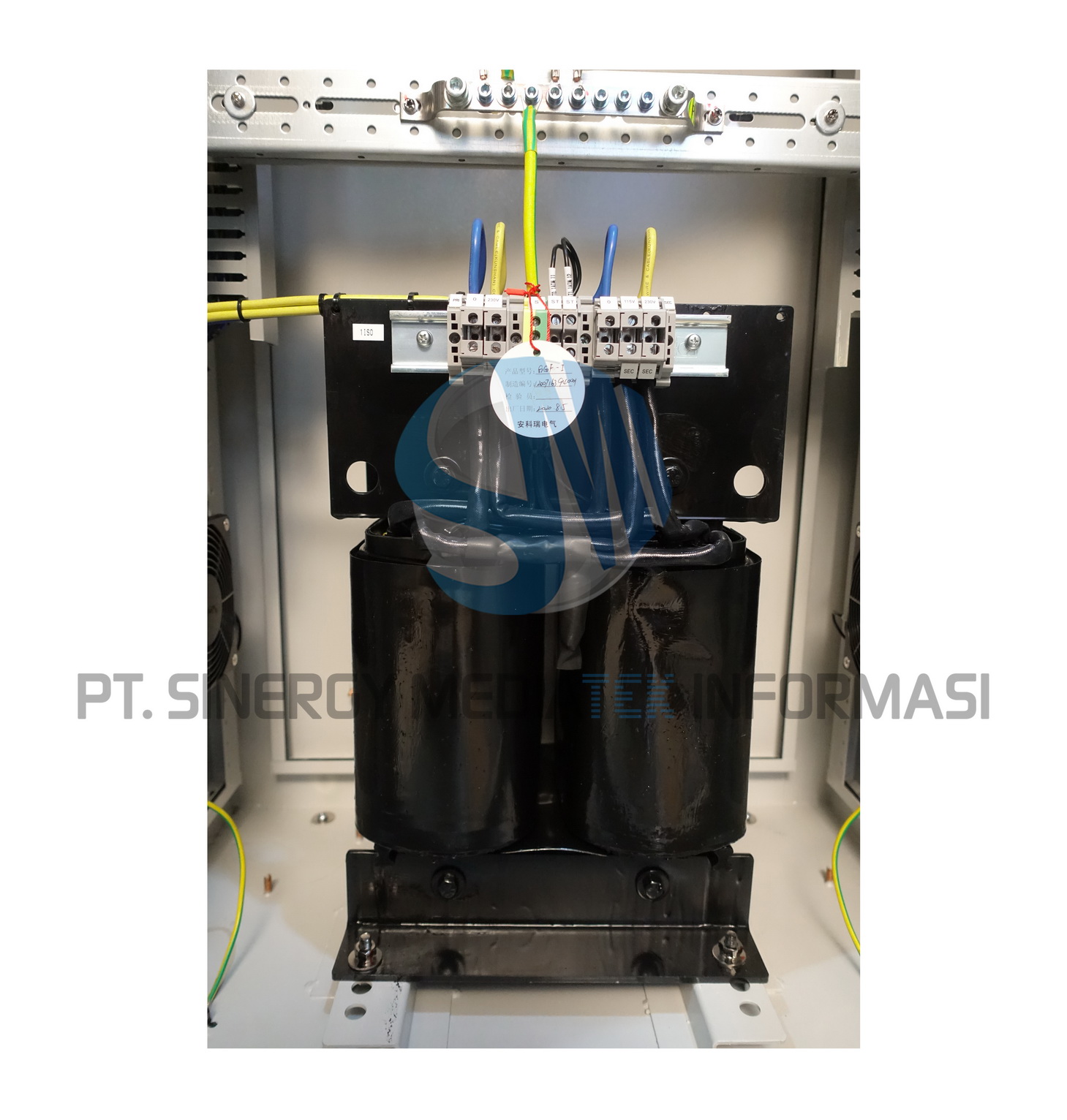

What is Isolation Transformer

An isolation transformer is a transformer used to transfer electrical power from a source of alternating current (AC) power to some equipment or device while isolating the powered device from the power source, usually for safety reasons. Isolation transformers provide galvanic isolation; no conductive path is present between source and load.

This isolation is used to protect against electric shock, to suppress electrical noise in sensitive devices, or to transfer power between two circuits which must not be connected. A transformer sold for isolation is often built with special insulation between primary and secondary, and is specified to withstand a high voltage between windings.

Isolation transformers block transmission of the DC component in signals from one circuit to the other, but allow AC components in signals to pass. Transformers that have a ratio of 1 to 1 between the primary and secondary windings are often used to protect secondary circuits and individuals from electrical shocks between energized conductors and earth ground. Suitably designed isolation transformers block interference caused by ground loops. Isolation transformers with electrostatic shields are used for power supplies for sensitive equipment such as computers, medical devices, or laboratory instruments.